Anilox | Manufacturing Process

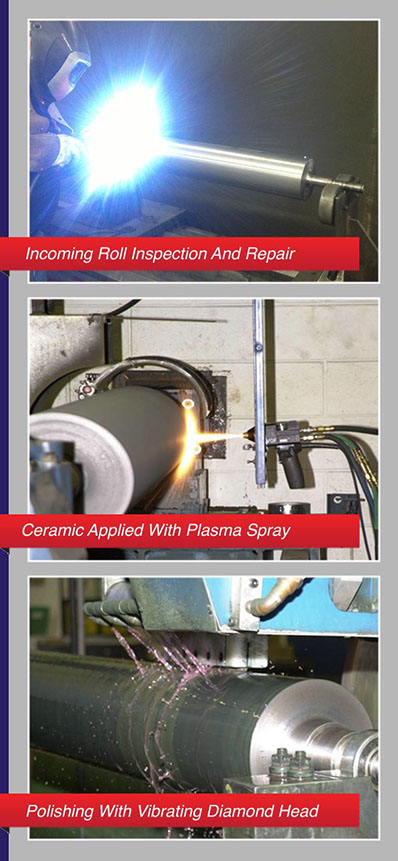

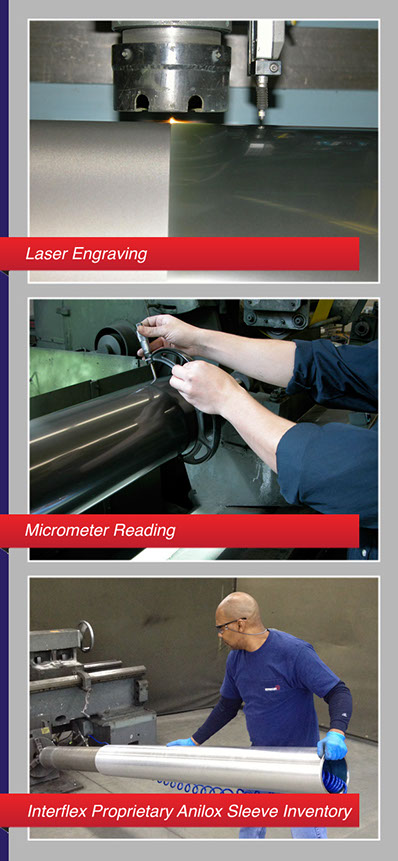

Each incoming roll is inspected for diameter runout via micrometer check, and wall thickness via meter.

The surface is then prepped via sandblasting and shot peening.

The fresh surface is then sprayed with a plasma containing ceramic particulates.

The ceramic roll is then polished to a 2.00 Ra mirror finish via a vibrating diamond head.

The polished roll is then mounted on the latest technological laser engraving machine, checked for a tolerance of .0002 TIR, and the roll surface is engraved to the desired specification.

The final product undergoes a series of pass/fail inspection criteria before being shipped to the customer.